As the industry carries on to evolve, collaboration involving technologies companies, regulatory bodies, and pharmaceutical companies is going to be essential to addressing issues and seizing opportunities in cleanroom sterilization.

The procedures employed for identification of isolates must be confirmed working with indicator microorganisms (see

The challenge will be to validate these new methods and make sure they meet up with regulatory requirements although delivering tangible Advantages with regards to sterilization efficacy and operational efficiency.

The focus of particles will depend on their diameter; for this reason The larger particles will probably be a lot less in selection compared to smaller particles in almost any cleanroom ecosystem.

The applying of Federal Standard 209E to clean rooms and other managed environments within the pharmaceutical industry has been utilized by makers of clean rooms to supply a specification for building, commissioning, and retaining these amenities.

Operational Qualification (OQ): Analytical calculation of apparatus operational potential is completed while the piece of apparatus is in operation.

Product Circulation —The stream of material and personnel moving into managed environments need to observe a specified and documented pathway that's been decided on to cut back or limit the probable for microbial contamination of the solution/closure/container methods.

This design demands a lot within the pharmacy. To help deal with the large quantity and distribution of medications, the pharmacy at Rust is expanding to accommodate two hoods in both the USP 797 and 800 rooms, and also the footprint is getting rearranged for processing and supply breakdown tasks. Construction is phased and rapid-tracked to reduce disruption to operations.

Microbial checking can be evolving, with quick detection strategies replacing common progress-based techniques. Systems which include ATP bioluminescence and PCR-dependent devices can provide brings about hrs instead of times, allowing for for speedier corrective steps when contamination is detected.

Personnel training is an important element of preserving sterility in pharmaceutical cleanrooms. here As cleanroom technologies and sterilization techniques evolve, so also need to the techniques to schooling cleanroom personnel.

These coatings can appreciably reduce the frequency of manual cleaning and disinfection processes, likely lowering the risk of introducing contaminants for the duration of these processes.

Very same as restrictions, so do the approaches for fumigation. The adoption of recent procedures and consistent adjustment in the previous ones assurance the cleanliness of clean rooms, and that is important for the pharmaceutical industry.

Pharmaguideline is really a pharmaceutical blog site where pharmaceutical concepts are discussed in quite simple and simply easy to understand language for specialists and pupils. All posts and SOPs are composed by Ankur Choudhary.

The area for being swabbed is defined using a sterile template of correct sizing. Generally speaking, it is during the number of 24 to thirty cm2 click here . The microbial estimates are documented per contact plate or for every swab.

Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Scott Baio Then & Now!

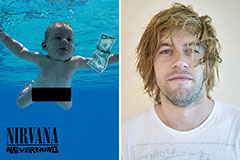

Scott Baio Then & Now! Spencer Elden Then & Now!

Spencer Elden Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!